Picking from Idea to Reality – Tips to Shape Your Plastic Visions

In a world where innovation reigns supreme, the journey from idea to reality has never been more exhilarating. Plastic, often maligned for its environmental impact, is also a remarkable material with endless possibilities. At the intersection of creativity and technology, there exists a realm where ideas take shape and become tangible realities. This is where we step in with our mantra: From Idea to Reality: We Shape Your Plastic Visions. Plastic, with its versatility and adaptability, has transformed industries across the globe. From automotive components to healthcare equipment, and from consumer goods to aerospace innovations, plastic is an integral part of our daily lives. However, the key to harnessing the true potential of plastic lies in the ability to envision, design, and produce customized solutions that address unique needs and challenges. At our core, we are problem solvers and visionaries. We collaborate with individuals, businesses, and industries to turn abstract ideas into concrete objects that serve a purpose. Our journey begins with the spark of an idea.

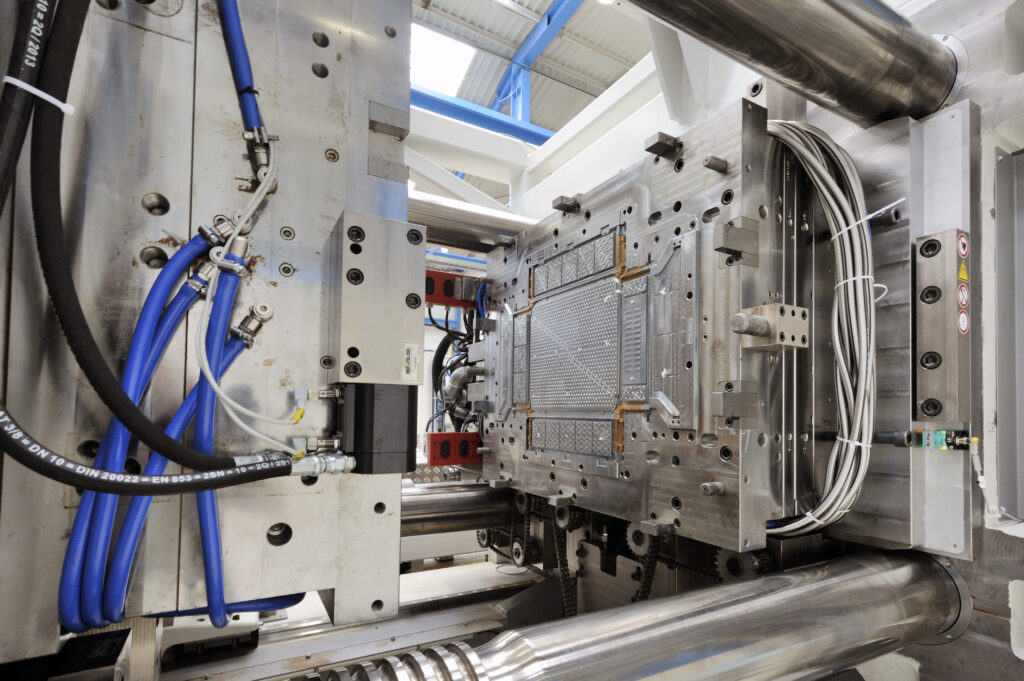

Whether it is a breakthrough product concept or an improvement on an existing design, we embrace the initial vision as the foundation for our work. The next phase of our process involves meticulous design and engineering. Our team of experts employs cutting-edge technology and precision tools to refine the concept into a practical blueprint. We take into account not only the aesthetic appeal but also the functionality and sustainability of the final product of injection moulding companies. Sustainability is a key element of our commitment to responsible manufacturing, and we continually seek ways to reduce environmental impact throughout our processes. With the blueprint in hand, we embark on the transformational journey from design to reality. Our state-of-the-art manufacturing facilities are equipped with the latest injection molding, extrusion, and 3D printing technologies. These capabilities allow us to shape plastics into virtually any form, from intricate and delicate structures to robust and resilient components. Quality is the cornerstone of our operations.

Our skilled technicians monitor every step of the production process to ensure that each piece meets the highest standards of durability, precision, and injection plastic molding safety. We understand that our clients trust us to deliver products that not only meet their expectations but also exceed them. Throughout this journey, we maintain open lines of communication with our clients. Collaboration and feedback are essential to our success. We consider our clients as partners, working together to bring their plastic visions to life. This approach fosters innovation and ensures that the end result aligns perfectly with the initial vision. In an era where customization and sustainability are paramount, we stand at the forefront of shaping plastic visions. From concept to creation, we are driven by the desire to turn ideas into tangible realities. Our commitment to quality, innovation, and responsible manufacturing makes us the preferred choice for those who seek to transform their plastic dreams into products that make a difference. We invite you to join us on this journey of creativity and innovation as we continue to redefine what is possible with plastic. Together, we will shape a brighter and more sustainable future, one idea at a time.